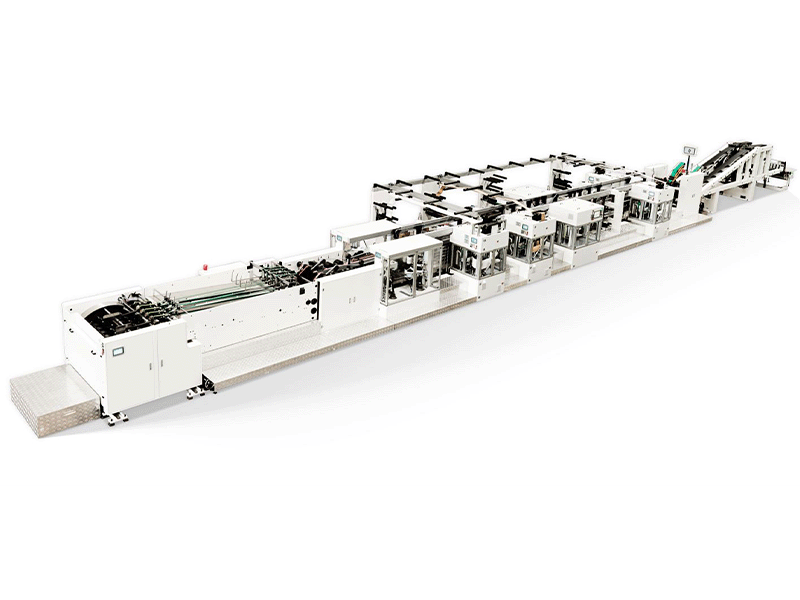

In today's fast-paced packaging industry, bottom gluing machines have become indispensable for manufacturers aiming to boost efficiency, reduce labor costs, and ensure high-quality packaging. These machines automate the critical process of folding and gluing the bottom flaps of cartons and paperboard packaging, transforming flat blanks into sturdy, ready-to-use boxes. This guide explores the types, working principles, benefits, applications, and latest innovations in bottom gluing machines, providing a comprehensive overview for businesses seeking to optimize their packaging lines.

What Are Bottom Gluing Machines?

Bottom gluing machines are specialized equipment designed to fold and glue the bottom flaps of cartons or paper bags, creating a secure base that supports the contents during handling and transport. They are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, electronics, and e-commerce packaging.

There are several types of bottom gluing machines, including

Crash-lock bottom folder gluers: These machines fold and glue the bottom flaps in a way that the box locks into place automatically when opened, providing a sturdy base without manual assembly. This is ideal for packaging heavier products or when ease of assembly is important.

Straight-line folder gluers: Used for standard carton boxes, these machines fold and glue flaps in a linear fashion, suitable for high-speed production lines.

Paper bag bottom gluing machines: Designed specifically for paper bags, these machines insert bottom cardboard, spray glue, and close the bottom automatically, ensuring precision and speed.

How Do Bottom Gluing Machines Work?

The operation of bottom gluing machines involves several key stages:

Feeding: Flat die-cut blanks or paper bags are automatically fed into the machine. These blanks are pre-scored and cut to the required dimensions.

Folding: The machine folds the minor (smaller) flaps first, followed by the major (larger) flaps. In some designs, one major flap is folded completely over the other to create a seamless bottom seal, which is essential for packaging heavy or moisture-sensitive products.

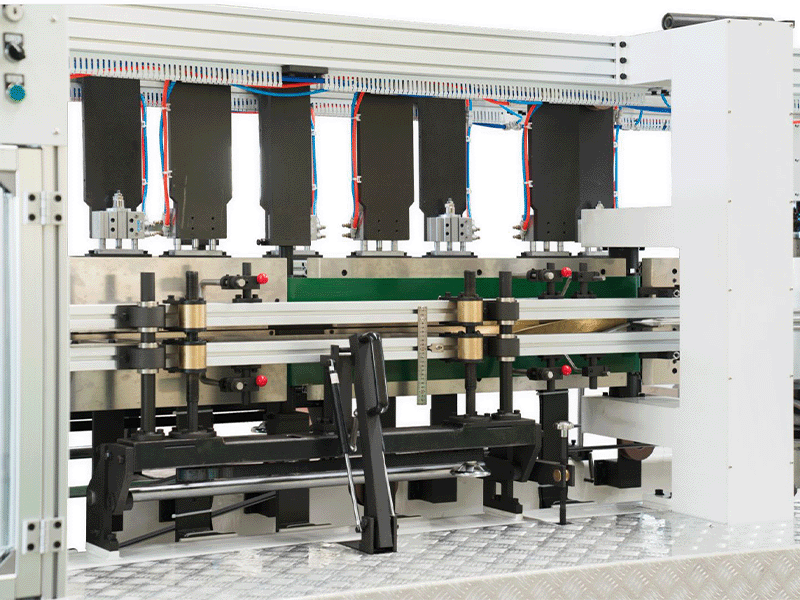

Gluing: Adhesive, typically hot melt or water-based glue, is applied precisely to the designated areas using nozzles or rollers. Advanced machines allow independent control of glue length and quantity for optimal bonding.

Compression: The folded and glued bottom is compressed under pressure to ensure a strong, durable bond. Compression rollers or plates hold the flaps together until the adhesive cures.

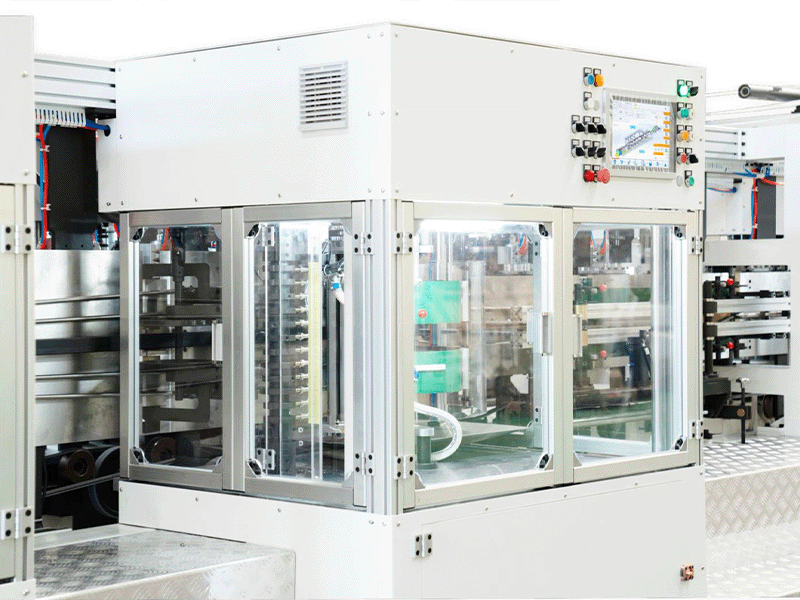

Inspection and Ejection: Automated sensors and cameras inspect the glued boxes for defects such as misfolds or insufficient glue. Defective products are ejected to maintain quality standards.

Stacking: Finished boxes or bags are stacked and prepared for shipment, often with integrated automated stacking systems.

Benefits of Using Bottom Gluing Machines

Using bottom gluing machines offers numerous advantages:

Increased Efficiency: Automated folding and gluing significantly speed up production compared to manual assembly, enabling high throughput suitable for large-scale packaging operations.

Consistent Quality: Precision glue application and folding mechanisms reduce errors and ensure uniform, strong seals, enhancing product protection and presentation.

Labor Savings: Automation reduces the need for manual labor, lowering operational costs and minimizing human error.

Versatility: Modern machines can handle a wide range of materials (cardboard, corrugated board, paperboard) and box styles (straight-line, crash-lock, multi-corner), adapting to diverse packaging needs.

Improved Safety: Automated inspection and ejection systems help maintain zero-defect production, reducing waste and rework.

Sustainability: Many bottom gluing machines support eco-friendly materials such as recycled paperboard and biodegradable adhesives, aligning with growing environmental regulations and consumer demand.

Key Applications and Industries

Bottom gluing machines are essential in packaging sectors where secure, durable bottoms are critical:

Food and Beverage: Packaging for frozen foods, dairy, eggs, beverages, and nutraceuticals often requires sealed bottoms to prevent contamination and leakage.

Pharmaceuticals and Cosmetics: Precise, hygienic packaging is vital for product safety and brand image.

Automotive and Electronics: Heavy or delicate parts benefit from crash-lock bottom cartons that provide stability during shipping.

E-commerce: High-speed, customizable packaging solutions meet the demand for fast, reliable order fulfillment.

Choosing the Right Bottom Gluing Machine

When selecting a bottom gluing machine, consider several important factors:

Box Type and Design: Different machines are optimized for straight-line, crash-lock bottom, or multi-corner boxes. The complexity of your box design will influence the best machine choice.

Material Compatibility: Ensure the machine can handle your packaging materials, whether cardboard, corrugated board, paperboard, or laminated materials.

Production Speed: Match the machine's capacity to your volume requirements to avoid bottlenecks or underutilization.

Glue Type: Choose between hot melt, water-based, or other adhesives depending on your product needs and environmental considerations.

Automation Level: Consider how much automation you need, including feeding, folding, gluing, inspection, and stacking capabilities.

Flexibility: If you require multiple box sizes or styles, look for machines with quick changeover features and modular designs.

Maintenance and Support: Evaluate the availability of technical support, ease of maintenance, and options for future upgrades or retrofits.

Budget: Balance initial investment with long-term operational savings and efficiency gains.

Conclusion

Bottom gluing machines are a cornerstone of modern packaging operations, delivering efficiency, precision, and reliability in producing secure carton bottoms. By automating the folding and gluing process, these machines reduce labor costs, improve product quality, and support sustainability initiatives.

If you are looking for the trusted bottom gluing machine supplier, look no further than DESHENG. We offer a wide range of bottom gluing machines to fit various applications.

Investing in the right bottom gluing machine tailored to your packaging needs can transform your production line, enhance your product's market appeal, and provide a competitive edge in today's dynamic packaging landscape.