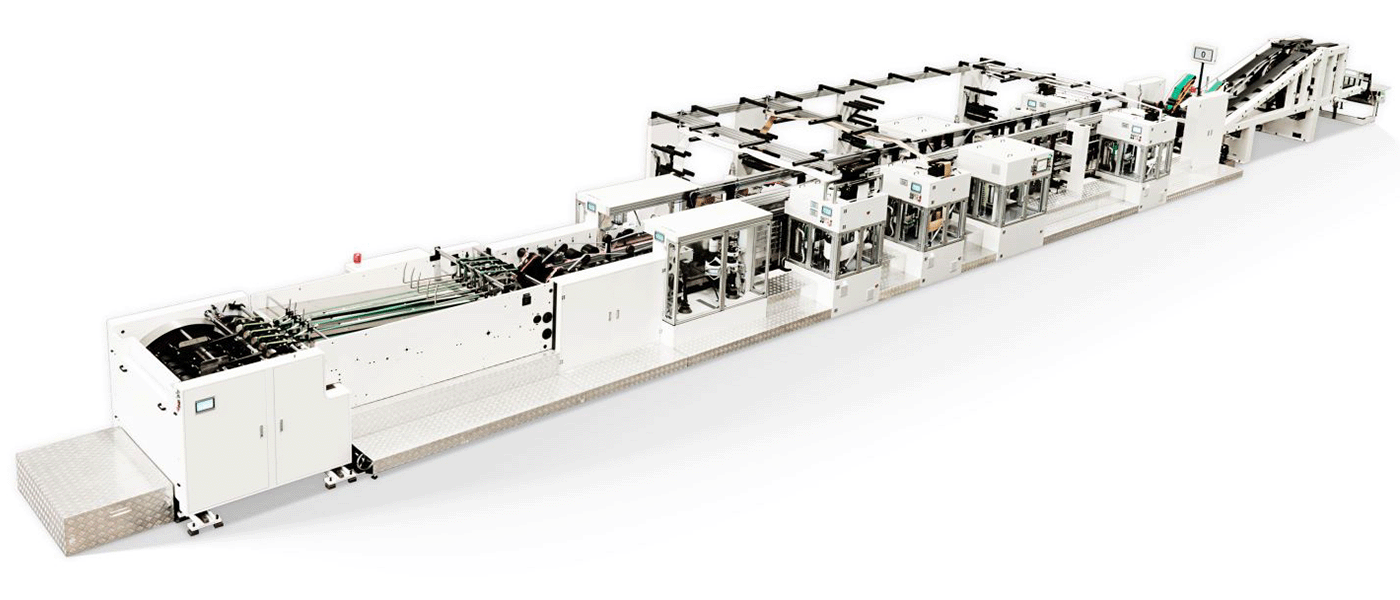

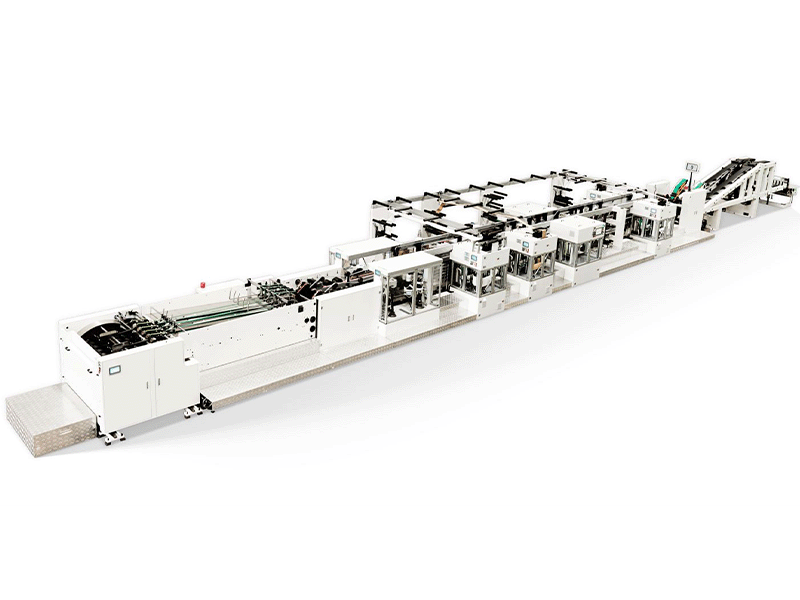

In the world of industrial packaging, valve paper bags are widely used to package powdered and granular products like cement, chemicals, flour, and construction materials. As demand for precision, speed, and automation continues to grow, businesses are turning to standard valve paper bag packaging machines to meet production needs while reducing operational costs.

These machines play a vital role in forming, filling, and sealing valve bags in a consistent and efficient manner. In this article, we’ll explore the top 5 benefits of using standard valve paper bag packaging machines in industrial applications, and why many companies around the world choose manufacturers like DESHENG for their packaging solutions.

1. Dramatically Increased Production Efficiency

One of the most obvious advantages of using a standard valve bag machine is the substantial increase in production efficiency. Traditional packaging methods often require manual labor, multiple handling steps, and considerable time per unit. By contrast, standard valve bag machines automate key stages of the process: bag forming, valve insertion, edge folding, gluing, and cutting.

Here's how efficiency is improved:

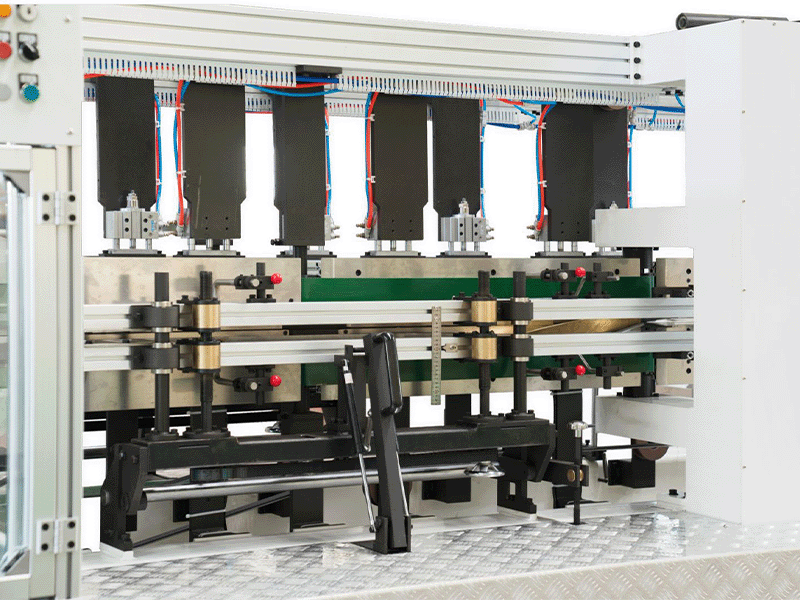

- Automation at every stage: These machines take flat paper rolls and convert them into fully formed valve bags, ready to be filled. The entire process is done at high speed with little human intervention.

- Reduced downtime: High-quality valve bag machines are built to operate continuously, with fewer interruptions for maintenance or material changeovers.

- High-speed output: Standard models can produce up to several thousand bags per hour, depending on configuration.

- Minimal operator training: With user-friendly control panels and programmable settings, operators can manage the entire process with minimal training.

Industries such as cement packaging, dry mortar production, and chemical powder processing benefit greatly from this level of automation.

2. Exceptional Packaging Quality and Consistency

Another core benefit of using standard valve bag machines is the consistent and precise quality of each bag. In industrial packaging, inconsistency can result in damaged goods, product spillage, poor shelf appearance, or even customer rejection.

How quality is assured:

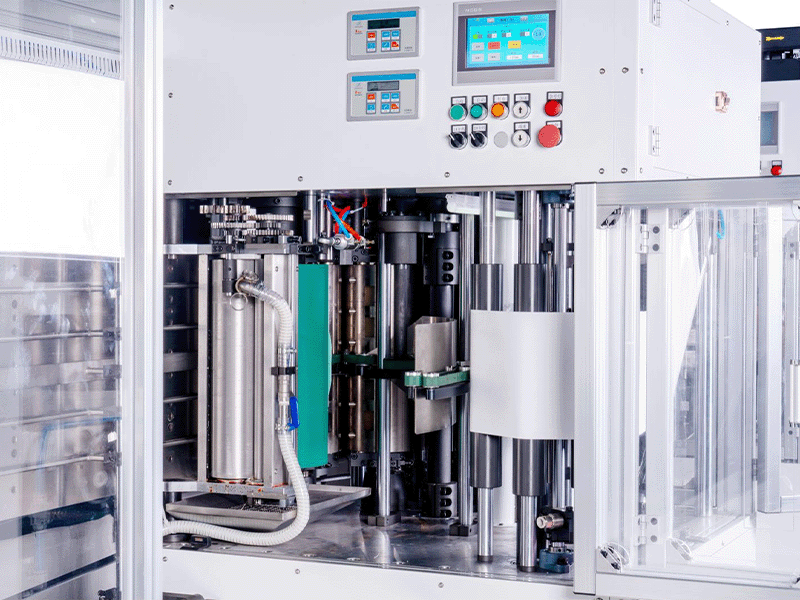

- Precision gluing ensures every valve and side seam is sealed tightly, minimizing the risk of leakage.

- Standardized dimensions of each bag make them compatible with automated filling lines and stacking systems.

- Clean cuts and neat folds give bags a professional finish, improving presentation.

- Stronger seals and reinforced structure reduce bag failure during handling or shipping.

The Standard Reinforced Valve Bag Manufacturing Machine, offered by DESHENG, is especially beneficial for products that require stronger bags. These machines are designed to produce multi-layer paper bags with enhanced load-bearing capacity, making them ideal for abrasive powders or heavy materials like tile adhesives, plasters, and pigments.

In competitive markets, such consistent packaging quality helps businesses maintain brand reputation and meet stringent industrial standards.

3. Broad Application Versatility Across Industries

Standard valve paper bag machines are highly versatile, capable of producing a wide range of bag types to meet different industrial requirements. This flexibility allows businesses to use the same machine across multiple product lines.

Industries and applications that benefit:

- Construction materials: Cement, sand, mortar, lime, fly ash.

- Chemicals: Fertilizers, resins, plastic powders, pigments.

- Agriculture: Animal feed, seeds, grains.

- Food industry: Flour, starch, sugar, spices.

Most standard valve bag machines can be configured to produce bags with different dimensions, valve types (internal or external), layers (2-5 ply), and paper materials (kraft, laminated, or PE-lined). This adaptability allows manufacturers to respond to market demands without changing equipment.

4. Significant Cost Savings in Labor and Waste Reduction

Although the initial investment in a valve bag packaging machine may seem substantial, the long-term cost savings are considerable. By automating the process, companies can reduce dependence on labor, minimize human errors, and decrease waste.

Cost-saving advantages:

- Lower labor costs: One operator can oversee an entire machine, eliminating the need for multiple workers at different stations.

- Minimized material wastage: Automated cutting and gluing reduce paper waste and misaligned bags.

- Fewer defective products: Improved accuracy means fewer rejected bags due to miscuts, leaks, or poor shape.

- Improved safety: Less manual handling reduces worker fatigue and injury, contributing to lower compensation claims and downtime.

5. Scalability and Long-Term Investment Value

As businesses grow, their packaging systems must keep up with rising demand. A key advantage of standard valve bag machines is their scalability. Whether a business is producing 10,000 or 100,000 bags per day, these machines can be adapted for higher capacity and integration with more advanced production lines.

What makes them scalable:

- Modular design: You can start with a semi-automatic machine and gradually add more automation modules.

- Compatibility with upstream/downstream equipment: Easily integrates with auto feeders, fillers, printers, and palletizers.

- Durability: High-quality components, such as servo motors and stainless steel contact parts, ensure long-term operation.

- Remote diagnostics: Advanced models from DESHENG offer IoT connectivity and remote support, making machine management smarter and more efficient.

For many manufacturers, the long-term ROI of these machines is clear. With proper maintenance, a DESHENG valve bag machine can operate reliably for 10+ years, making it a strategic capital investment.

Why Choose DESHENG for Your Valve Bag Packaging Needs?

As one of the leading suppliers in the valve bag machinery industry, DESHENG offers solutions that combine quality, customization, and service. The company specializes in both standard valve paper bag packaging machines and enhanced valve bag assembly machines, catering to diverse client needs.

Key advantages of working with DESHENG:

- Tailor-made configurations for different industries and bag types.

- Strong technical support, including on-site setup, training, and maintenance.

- Use of globally recognized electrical and pneumatic components.

- Competitive pricing with long-term performance guarantees.

Whether you are a small business upgrading your manual line or a large manufacturer seeking an integrated, fully automated solution, DESHENG delivers machines that are engineered for precision, speed, and reliability.

Conclusion

Standard valve paper bag packaging machines offer a powerful combination of automation, quality, and versatility for industrial producers. Their ability to enhance speed, reduce labor, improve consistency, and scale with business growth makes them an ideal choice across sectors like construction, agriculture, chemicals, and food processing.

With a trusted partner like DESHENG, manufacturers can ensure their packaging operations are future-ready — combining cutting-edge machinery with tailored solutions that improve productivity and profitability.