For manufacturers involved in cement, chemical, agricultural, and industrial granular product packaging, efficiency and consistency are no longer optional—they are essential for survival in a competitive global market. One question frequently asked by decision-makers is: Are valve paper bag packaging machines worth the investment?

Valve paper bag packaging machines represent a significant capital expenditure. However, they also offer substantial potential returns through improved productivity, reduced labor dependency, consistent bag quality, and long-term operational savings. As packaging requirements become more demanding and production volumes continue to rise, many manufacturers are re-evaluating traditional bag-making and packaging methods.

In this article, we take a comprehensive look at the true value of valve paper bag packaging machines, the key benefits they offer, and how integrated solutions from experienced suppliers like DESHENG help manufacturers achieve measurable returns on investment.

What Are Valve Paper Bag Packaging Machines?

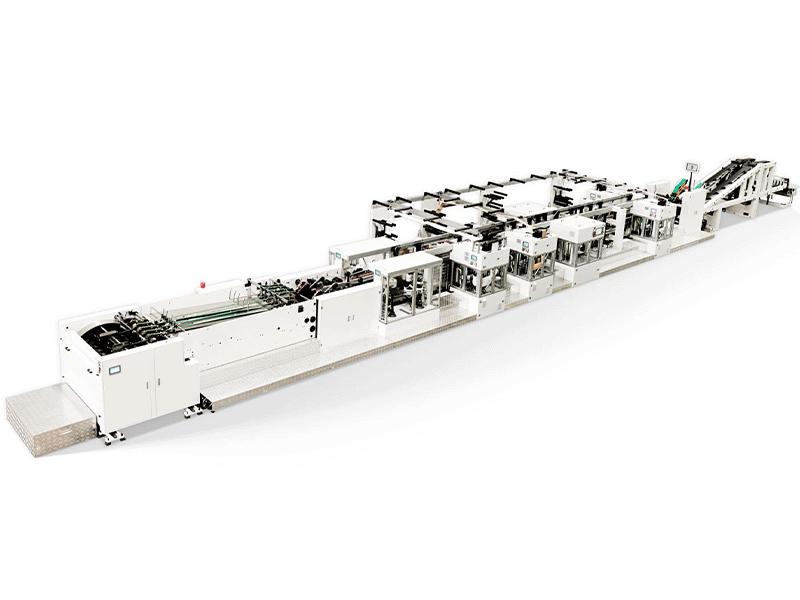

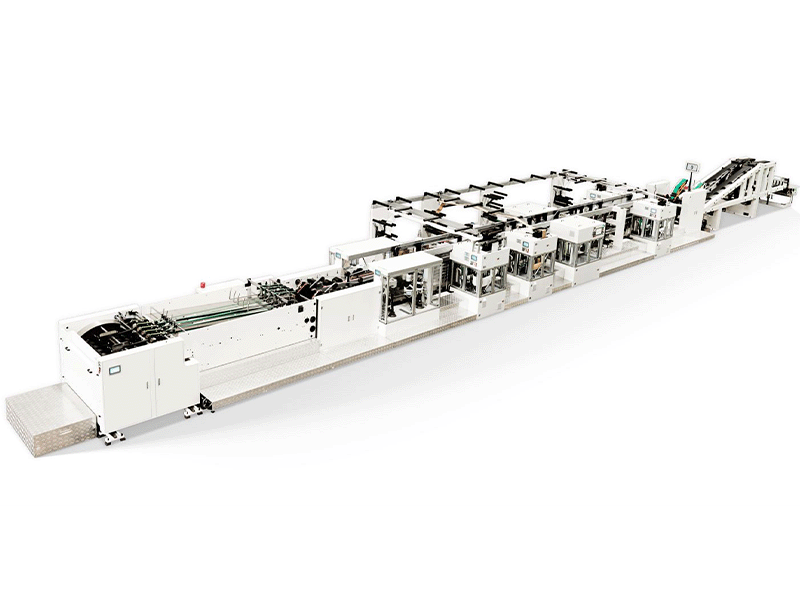

Valve paper bag packaging machines are specialized industrial systems designed to produce and package paper valve bags, which are widely used for filling powdered and granular materials. These machines typically form part of a complete valve bag production line, working in coordination with:

- Tube forming machines

- Valve bag making machines

- Valve bag base machines

- Stacking and palletizing systems

Unlike open-mouth bag systems, valve paper bag packaging machines require precise forming and sealing to ensure that bags can be filled quickly, sealed automatically, and transported safely without leakage.

Why Valve Paper Bags Are in High Demand

Before evaluating the investment, it's important to understand why valve paper bags themselves are so widely adopted.

Key advantages of valve paper bags:

- Fast, dust-controlled filling

- Self-closing valve design

- High load-bearing capacity

- Compatibility with automated filling lines

- Cost-effective and recyclable paper materials

These characteristics make valve paper bags the preferred choice for cement packaging, activated carbon, chemical powders, fertilizers, and other granular products.

As demand for these materials grows, so does the need for reliable valve paper bag packaging machines.

The True Cost of Traditional Packaging Methods

Many manufacturers still rely on semi-automatic or outdated bag production and packaging systems. While these systems may appear cheaper initially, they often result in hidden costs such as:

- High labor requirements

- Inconsistent bag quality

- Increased material waste

- Frequent machine downtime

- Limited scalability

Over time, these inefficiencies can significantly impact profitability and customer satisfaction, especially for high-volume operations.

Key Benefits of Valve Paper Bag Packaging Machines

1. Increased Production Efficiency

One of the most compelling reasons to invest in valve paper bag packaging machines is production speed. Modern systems are designed for high-speed, continuous operation, enabling manufacturers to meet large order volumes without expanding workforce size.

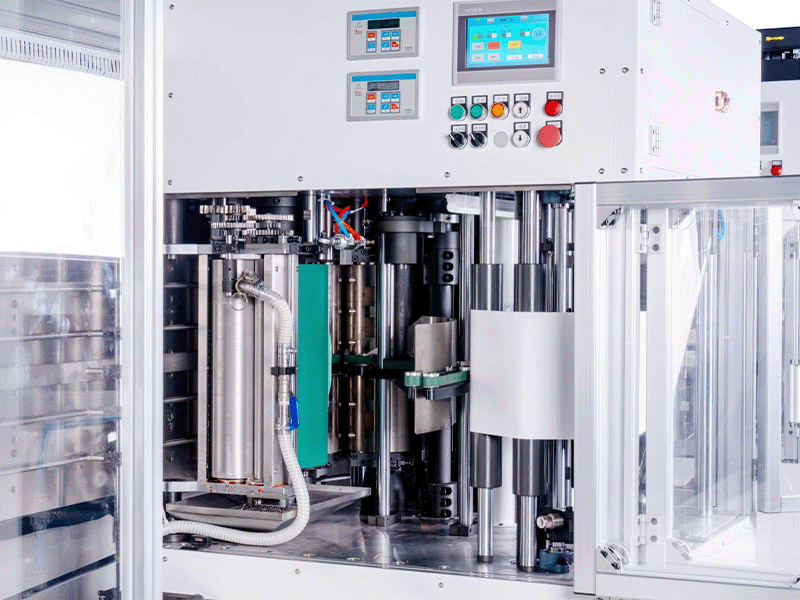

By integrating tube forming, valve insertion, and base forming into a streamlined workflow, these machines dramatically reduce cycle times per bag.

2. Consistent and Reliable Bag Quality

Consistency is critical in industrial packaging. Variations in bag dimensions, valve alignment, or sealing quality can lead to filling problems and product loss.

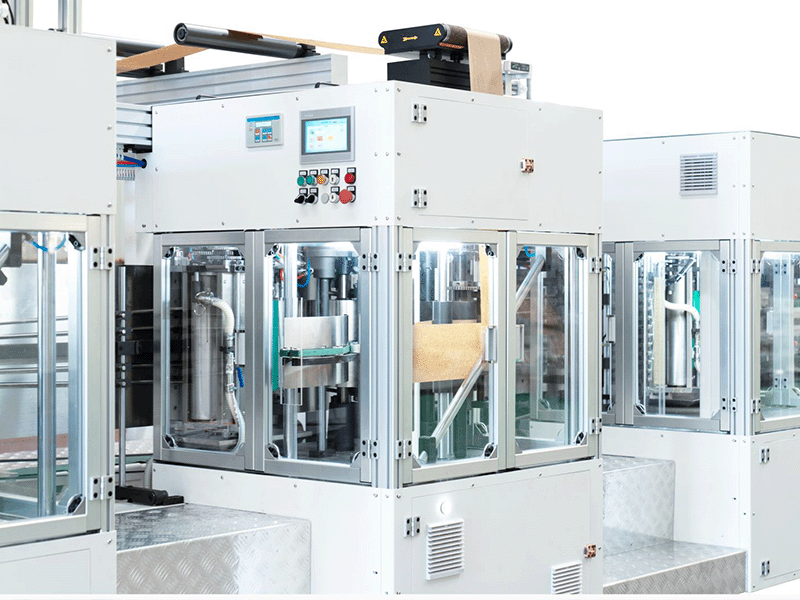

Valve paper bag packaging machines use precise mechanical structures and intelligent control systems to ensure:

- Uniform bag dimensions

- Accurate valve placement

- Strong and reliable seals

This consistency is especially important in cement bag manufacturing, where bags must withstand heavy loads and rough handling.

3. Reduced Labor Dependency

Automation is a major advantage of modern valve paper bag packaging equipment. Compared to manual or semi-automatic systems, fully integrated machines significantly reduce the need for skilled labor.

This not only lowers labor costs but also minimizes production risks caused by operator variability or workforce shortages.

4. Lower Material Waste and Operating Costs

Material waste directly affects profit margins. Poorly formed bags, misaligned valves, and inconsistent sealing all lead to rejected products.

High-quality valve paper bag packaging machines—such as those offered by DESHENG—are engineered to optimize paper usage while maintaining structural strength, helping manufacturers reduce scrap rates and improve material efficiency.

The Role of Intelligent Automation

Real-Time Monitoring and Control

Modern valve paper bag packaging machines are equipped with intelligent control systems that monitor critical parameters such as speed, tension, and alignment in real time.

These systems automatically adjust operating conditions to maintain optimal performance, reducing downtime and preventing defects before they occur.

Predictable and Scalable Production

With intelligent automation, manufacturers can scale production with confidence. Once parameters are set, machines deliver consistent results across long production runs, making them ideal for high-volume industrial applications.

DESHENG places strong emphasis on intelligent system integration, ensuring that each machine performs reliably under demanding production conditions.

Applications Across Multiple Industries

Valve paper bag packaging machines are widely used across industries that require durable, high-capacity packaging.

Cement and Construction Materials

Cement packaging demands strong bags with precise valve structures. Automated packaging machines ensure uniform quality and high output, making them essential for cement plants and building material manufacturers.

Chemical and Mineral Products

For products such as activated carbon and mineral powders, consistent internal volume and dust-controlled filling are critical. Valve paper bag packaging machines meet these requirements efficiently.

Agricultural Products

Fertilizers and agricultural granules require packaging solutions that balance durability with cost efficiency. Intelligent packaging machines help producers handle seasonal demand spikes without sacrificing quality.

Are Valve Paper Bag Packaging Machines Worth the Investment?

Evaluating Return on Investment (ROI)

While the upfront cost of valve paper bag packaging machines can be substantial, the long-term ROI often justifies the investment. Key contributors to ROI include:

- Increased output capacity

- Reduced labor and operational costs

- Lower material waste

- Improved product consistency

- Reduced downtime

For manufacturers producing large volumes of valve paper bags, these benefits translate into measurable financial gains over time.

Why Manufacturers Choose DESHENG

When evaluating investment value, the choice of equipment supplier is just as important as the machine itself.

DESHENG is a specialized manufacturer of valve paper bag packaging machines and complete production line solutions. Rather than offering standalone equipment, DESHENG focuses on system-level optimization, ensuring seamless integration between:

- High-speed tube forming machines

- Valve bag making machines

- Valve bag base machines

DESHENG's solutions are designed for industrial reliability, high-speed operation, and intelligent automation—key factors that directly impact investment returns.

Building a Complete Valve Paper Bag Packaging Line

A valve paper bag packaging machine delivers maximum value when it is part of a fully integrated production line.

DESHENG supports manufacturers in building complete systems that align forming speed, valve insertion, and base sealing processes. This holistic approach minimizes bottlenecks and ensures stable, high-efficiency production.

Future Outlook: Automation and Smart Packaging Lines

As industrial packaging continues to evolve, future-ready manufacturers are investing in:

- Higher levels of automation

- Smart diagnostics and predictive maintenance

- Energy-efficient machine designs

- Fully integrated production lines

Valve paper bag packaging machines are at the center of this transformation, enabling manufacturers to remain competitive in both cost and quality.

Conclusion

So, are valve paper bag packaging machines worth the investment? For manufacturers handling cement, chemical, agricultural, or granular products, the answer is increasingly yes.

While the initial cost may be higher than traditional systems, the long-term benefits—higher efficiency, consistent quality, reduced waste, and scalable production—make valve paper bag packaging machines a strategic investment.

With integrated, intelligent solutions from experienced suppliers like DESHENG, manufacturers can move beyond short-term cost considerations and build efficient, future-proof packaging operations.