In today's competitive industrial packaging sector, choosing the right valve bag forming machine is a strategic decision. Whether you're producing valve bags for cement, chemicals, food powder, or other bulk materials, investing in the right equipment will directly influence your efficiency, product quality, and operational costs.

With many types of valve paper bag machines and paper bag forming equipment available in the market, how do you choose the right one for your business? This article outlines the five key factors every buyer should consider before purchasing a valve bag forming machine, helping you build a productive and future-ready paper valve bag production line.

1. Machine Compatibility with Bag Specifications

Not all industrial valve bag machines are built to handle the same range of bag formats or materials. The first thing to consider is whether the machine supports your desired:

- Bag size range (length, width, gusset depth)

- Bag types – such as standard valve bags, reinforced valve bags, or block bottom bags

- Paper types – including 2-ply, 3-ply, or laminated kraft paper

- Glue requirements – hot melt, cold glue, or water-based adhesives

If you're manufacturing cement valve bags, for example, you'll need a machine that ensures high strength and resistance to tearing. Meanwhile, food-grade packaging may demand precise sealing and clean glue application.

A versatile valve paper bag machine with adjustable settings ensures flexibility for multi-product packaging needs. Leading manufacturers like DESHENG offer machines that can be easily configured to suit different bag structures and glue systems, helping you reduce changeover time and maximize uptime.

2. Production Speed and Output Efficiency

Production output is a top priority in large-scale valve bag manufacturing. The performance of your paper bag forming equipment should meet your current demand while leaving room for future scaling.

Important factors to evaluate include:

- Bags per minute (BPM) rate under continuous operation

- Machine cycle time and production yield per shift

- Downtime rates due to changeovers, cleaning, or maintenance

A slow or inconsistent machine can hold back your entire packaging line. High-speed automatic valve bag machines, like those produced by DESHENG, can form and seal bags with impressive precision and consistency, helping factories achieve stable output with minimal human intervention.

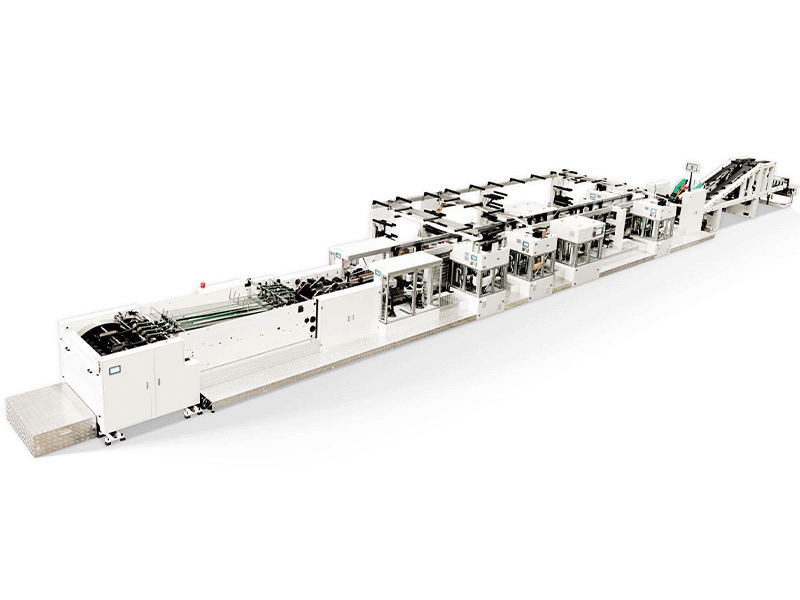

Also, consider whether the machine integrates seamlessly with your bottom pasting machine, stackers, conveyors, or filling lines for a fully automated valve bag packaging system.

3. Automation Level and Operator Interface

Modern valve bag packaging machines feature advanced automation to reduce labor costs and increase accuracy. When reviewing machines, ask whether they offer:

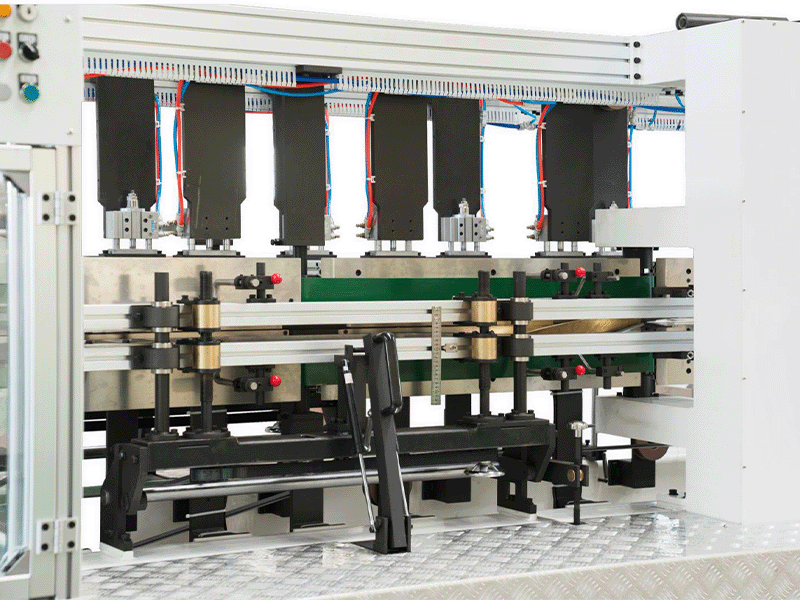

- PLC-controlled operation with touchscreen interface

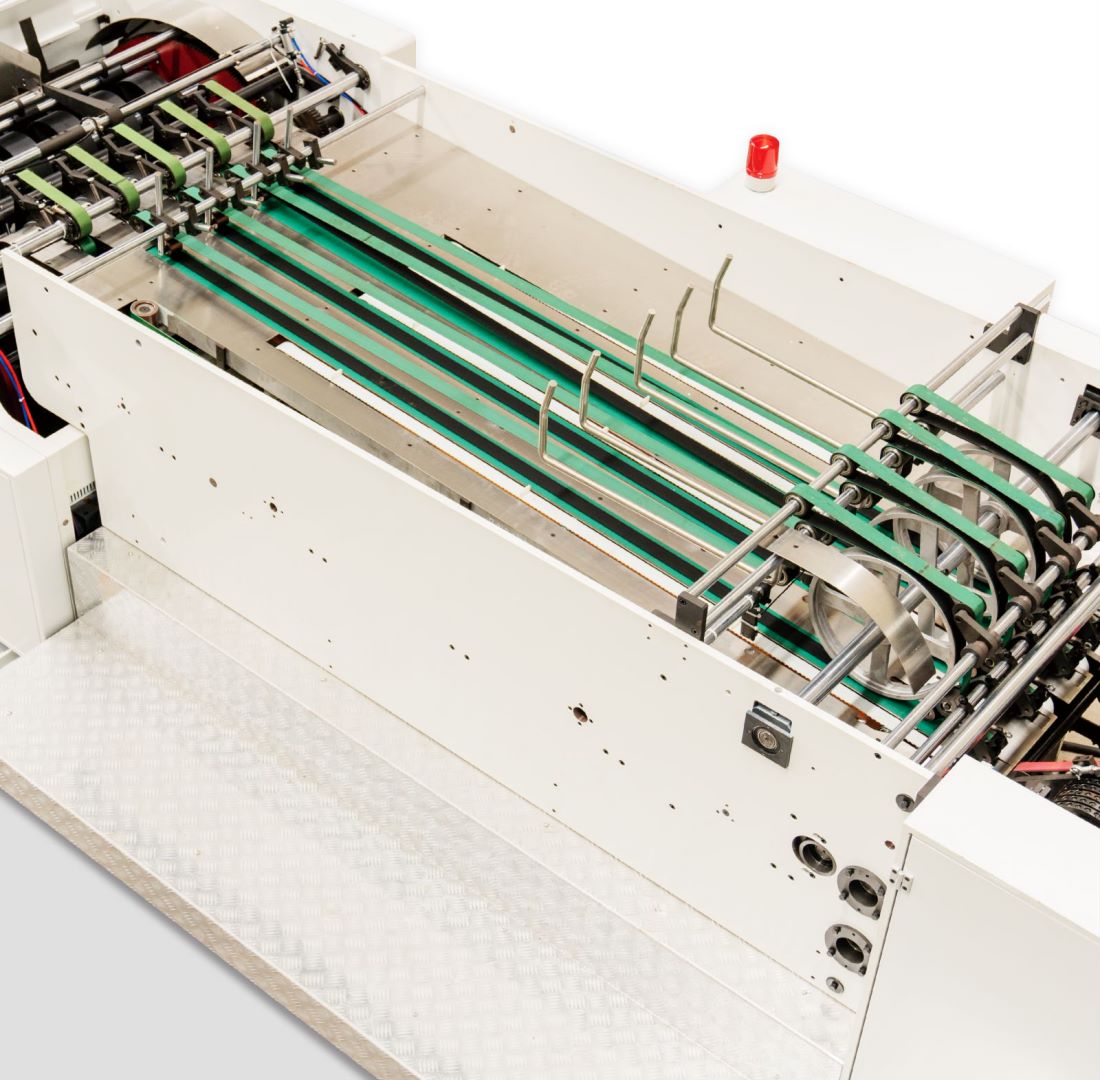

- Automatic paper feeding, folding, and gluing

- Error detection sensors for misalignment or glue failure

- Auto-stop and diagnostic systems

- Quick format switching for multiple bag sizes

An intuitive HMI (Human-Machine Interface) allows easy operation by semi-skilled workers, while remote support capabilities or software upgrades help in predictive maintenance and diagnostics.

If you plan to run a high-volume paper bag production line, automation will be a critical factor for efficiency. For example, DESHENG's automatic valve bag forming machines come with real-time monitoring and glue control systems, helping manufacturers reduce material waste and ensure perfect bag alignment every time.

4. Durability, Service Life, and Maintenance Support

Valve bag making equipment is a long-term investment. Machines built from durable materials like stainless steel and wear-resistant alloys last longer and require less frequent maintenance.

When evaluating durability, ask:

- Is the machine structure strong enough for 24/7 operation?

- Are the critical components like glue applicators, rollers, and pasting arms easy to clean and replace?

- What's the frequency of scheduled maintenance?

- How easy is it to access replacement parts and technical support?

Another important factor is after-sales service. A reliable manufacturer should offer:

- Fast response for troubleshooting

- Local or remote technical support

- Operator training

- Documentation and manuals

- Spare parts inventory

DESHENG, for example, offers global support for clients, along with comprehensive training and documentation. That means less downtime, faster problem-solving, and a longer equipment lifespan.

5. Customization Options and Future Scalability

A good valve paper bag machine should not only meet your current needs but also adapt to your future production goals. Evaluate how customizable the equipment is.

Customization options may include:

- Different glue types (hot melt, water-based, or double glue system)

- Bag printing integration

- Dust collection systems for clean-room environments

- Flexible feeding systems for different paper qualities

- Add-on units for bundling, labeling, or inspection

Also consider if the machine can be upgraded to work with enhanced valve bag assembly systems or smart factory integration later on. Modular equipment design allows easy integration with upstream or downstream automation, making your production line scalable and future-proof.

DESHENG offers both standard and enhanced valve bag machine series, allowing clients to grow their packaging capacity without replacing the entire system.

Bonus Tip: Consider the Total Cost of Ownership (TCO)

Don't make the mistake of only comparing upfront prices. The total cost of ownership includes:

- Energy consumption

- Spare part replacement frequency

- Labor costs for operation

- Downtime losses

- Preventive maintenance needs

A slightly more expensive industrial packaging machine with lower running costs and superior support may offer far better long-term ROI than a cheaper but less reliable model.

Why Choose DESHENG as Your Valve Bag Machine Supplier?

With years of experience in paper bag making equipment, DESHENG is a trusted manufacturer of valve bag forming machines, bottom pasting machines, and complete valve bag packaging solutions.

Here's why global customers choose DESHENG:

- Full line of valve bag manufacturing machines, including standard and reinforced formats

- High-speed, high-accuracy performance

- Flexible customization and integration

- Strong after-sales and training support

- Export experience to Asia, Europe, Africa, and the Americas

Whether you're producing cement valve bags, chemical powder bags, or eco-friendly kraft paper bags, DESHENG can help build a solution that fits your factory layout and production goals.

Conclusion

Investing in the right valve bag forming machine is about more than just price — it's about choosing a solution that delivers speed, quality, flexibility, and long-term value. By focusing on the five key factors—bag compatibility, output efficiency, automation, durability, and scalability—you can confidently select equipment that supports your packaging success.

Let DESHENG be your partner in building a reliable and efficient valve paper bag production line.